BRUSHLESS ENGINE

HOME » AUTOMATISMS » MOTOR BRUSHLESS

WHAT IS A BRUHSLESS ENGINE?

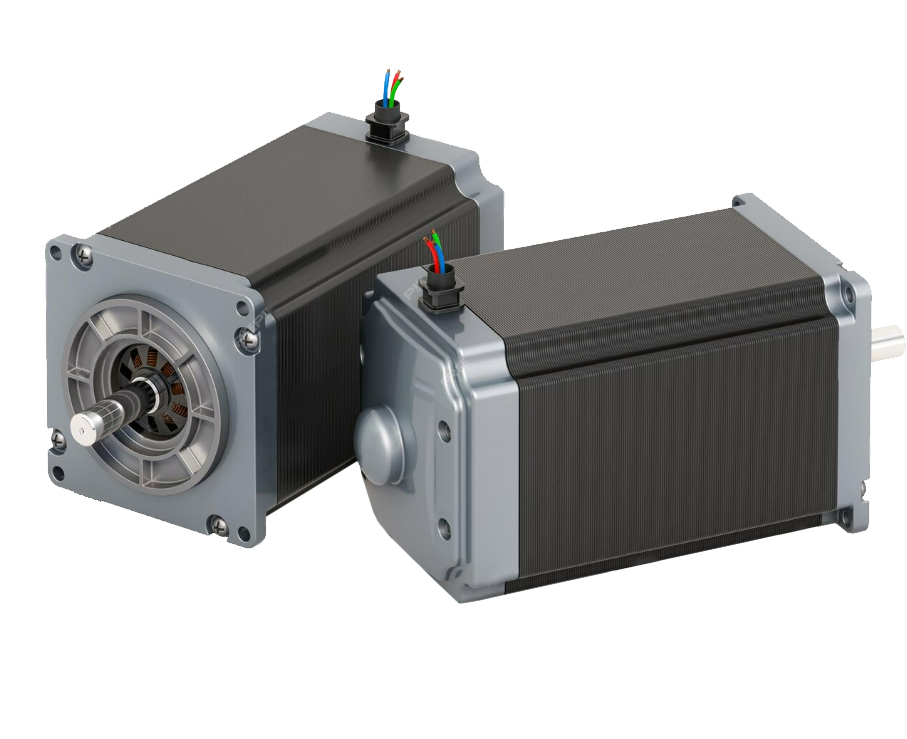

The brushless motor is a device that, as the name suggests, doesn’t need any brushes, unlike conventional electric motors with a commutator. This is a three-phase digital motor with an orientated permanent magnetic field, whose components are designed using the best raw materials in order to be more resistant and durable.

WHY INVEST IN BRUSHLESS MOTORS?

WHAT ARE THE ADVANTAGES OVER A CONVENTIONAL ENGINE?

SILENCE

With no noise coming from the brushes, brushless machines also have precision ball bearings that guarantee absolute silence.

SECURITY

Sem fricções entre elementos, nem potenciais faíscas, o equipamento pode ser aplicado em ambientes inflamáveis / explosivos, contrariamente aos motores convencionais.

REDUCED MAINTENANCE

With no high-wear components and robust materials, bruhless motors have a longer service life that requires less maintenance than ordinary motors.

ENERGY EFFICIENCY

By eliminating the mechanical resistance of the brushes, energy losses are almost completely eliminated and the rotor achieves a higher rotational speed.

INTENSIVE USE

By operating precisely, reducing inertia and harnessing all the energy, brushless drives work safely and uninterruptedly for a long time.

LINEAR OPERATION

Without overheating and making efficient use of energy, the brushless accelerates and decelerates very linearly and without jerking, achieving higher rotational speed

COMPACT DIMENSIONS

With fewer and more compact components, a brushless motor has a smaller footprint and can be used in places with space restrictions.

BEST PRICE/POWER RATIO:

Despite the slight difference in value, the ratio is substantially better, resulting in more power and greater load-carrying capacity.

comparison image

(move the image from the centre tab)

HOW DOES IT DIFFER FROM A CONVENTIONAL ENGINE?

Electric motors transform electrical energy into mechanical energy. In conventional motors, the commutator of the rotating rotor receives the electrical charge from graphite brushes that conduct it through direct contact with the rotor. This creates a magnetic field that generates rotational movement via special magnets.

In Brushless Motors, the commutator and brushes are replaced by coils wound on a static core – instead of the coils being located on a moving rotor – which creates a current flow that moves the rotor. These brushless motors can have anything from a set of three windings to a set of eight pole pairs.